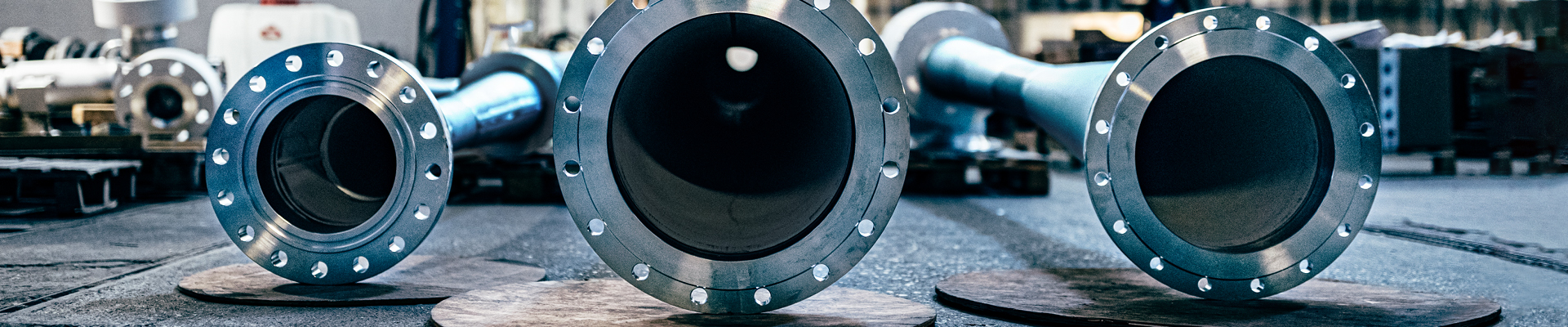

| Company profile | Körting Hannover has established itself as a leading manufacturer for products in vacuum and environmental technology. The focus on engineering and core competencies in niche markets worldwide makes the company an important partner in the process industry. In the product areas of jet pumps/vacuum technology and waste gas purification/environmental technology, the tasks are individually analysed, solutions developed and implemented, tailored to the respective situation of the customer.

|

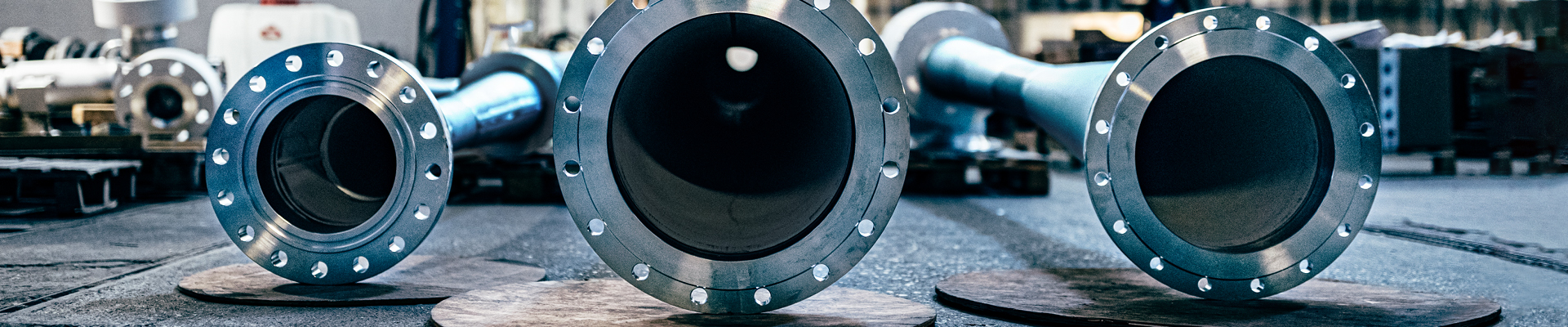

| Products & Services | Körting Caustic Recovery Plants (CRP) are used during the mercerisation process. In this finishing process, tensioned textile fibres are treated with caustic soda. The caustic soda solution is washed out of the fibres and, as a diluted caustic solution (weak lye), it’s a waste product and must be disposed of at high cost. A Körting Caustic Recovery Plant (CRP) allows this waste product to be reconcentrated and almost fully recovered. This means that the caustic soda solution can be used again in the process and does not have to be disposed of separately. This protects the environment and reduces operating costs dramatically.

|

| References and export activities | Over 40 references in India since 1997; e.g.

– Welspun

– Vardhman

– Trident

|

| Target group | Any textile finishing mill with mercerisation.

|

| Competitive advantages | – global market leader in CRP

– caustic soda (weak lye) used can be recovered

– strong lye recovered can be cleaned with hydrogen peroxide

– quality of the vapour condensate is excellent because swirl droplet separators are used

– vapour condensate has a low pH-value (can be used in other processes, e.g. washing in the mercerising machine, bleaching)

– plant is highly energy efficient (the hot water generated is used)

|