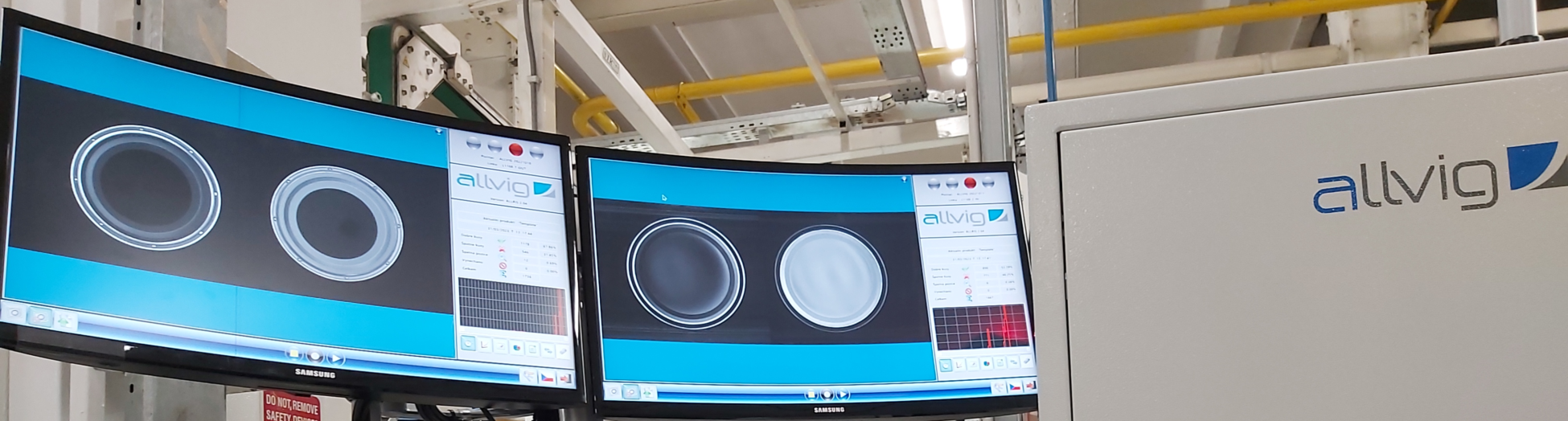

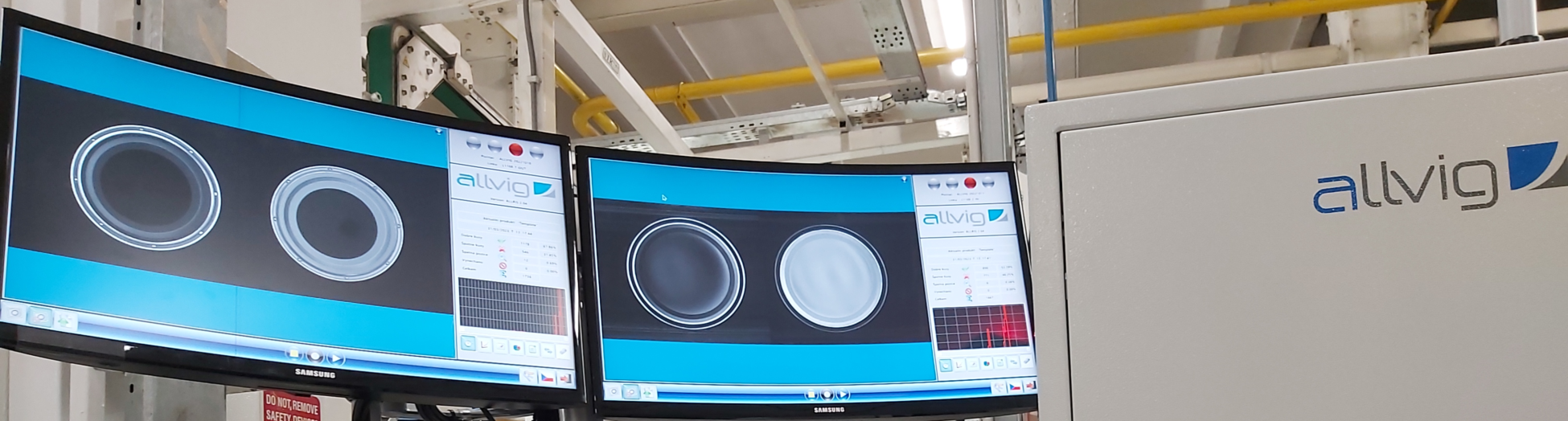

| Company profile | Allvig Technology GmbH develops industrial contactless quality

control systems to provide automatic quality control with emphasis on

surface analysis, print inspection, position control, measurement, and

completeness check.

Their solutions for defects detection and quality control cover

numerous products, among others, plastic or paper cups, lids and

bottle caps, canisters and dispensers and metal parts. Thereby, the

company manages to address various industries from the packaging

and rubber-plastics sector to metal goods producers and the

automotive industry.

Allvig’s competence is based upon 30 years of experience in

automatic industrial quality control. Extensive communications with

manufacturers and detailed feedback revision gives them first-hand

knowledge about changing needs and concerns in production

processes. Each specific case is initiated through a comprehensive,

nonbinding feasibility analysis examining the problem description and

samples of production.

|

| Products & Services | In-Line visual quality control systems for high speed production (up to 60pcs/sec)

|

| References and export activities | – Trivium Packaging

– Paccor

– Alfons Haar

– Witoplast

– TinCap

– KTK

|

| Target group | Target market:

– Metal packaging

– Plastic packaging

– Automotive sector

|

| Competitive advantages | Allvig systems ensures minimal pseudo-rejections with reliable defect detection.

In addition to this, our sophisticated technology verifies the detection of low-contrast and intricate

defects alleviating producers from these worries.

The software for the system is navigated via convenient, conceptually clear, and

remarkably intuitive multilingual user interface.

Remote troubleshooting online and offline is available.

|

| Ideal Business Partners | We are looking for industrial partners who do packaging as well as producers of

packaging machines. We offer cross selling collaborations

|