Cevotec GmbH

German companiesView Profile

Summary

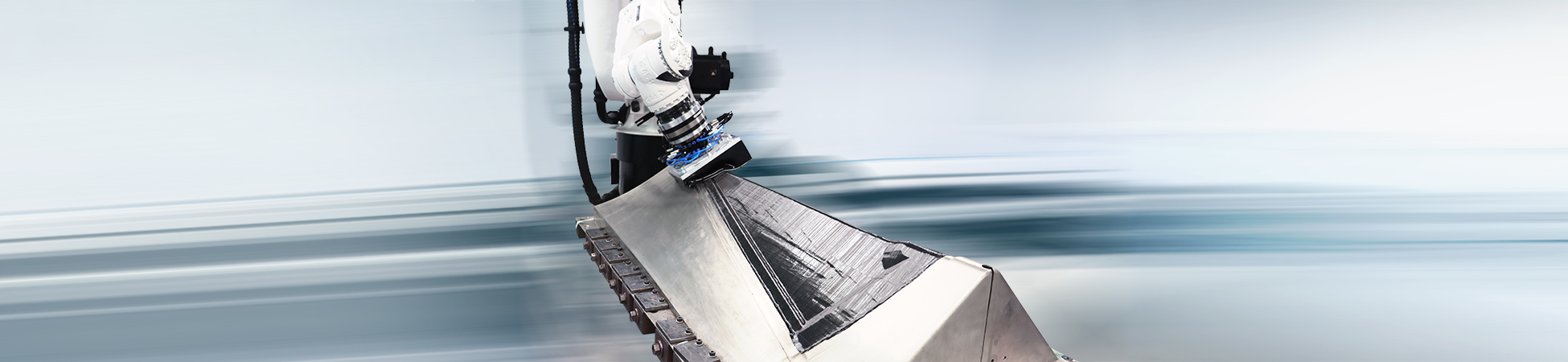

| Short Business Description | Cevotec enables manufacturers to produce complex composites in high volume and superior quality – with robotic lay-up automation |

General information

| Company profile | Cevotec empowers manufacturers to produce complex composites in high volumes and superior quality by using Fiber Patch Placement (FPP) technology. Our robotic SAMBA systems automate the precise placement of carbon fibers, glass fibers, adhesive films, and other technical fibers on complex 3D geometries, supported by our CAD-CAM software ARTIST STUDIO. The automated, quality-controlled lay-up process enables our customers in aerospace and renewable energy to meet strict quality, cost, and sustainability goals, with up to 60% savings in production time and cost. |

| Products & Services | – SAMBA lay-up automation systems |

| References and export activities | Installations worldwide (publicly announced): |

| Target group | Aerospace OEM, tier 1 & 2 involved in composites manufacturing & development; composite pressure vessel manufacturers and developers |

| Competitive advantages | 1. Enable lay-up automation on geometries where other technologies face limitations |

| Ideal Business Partners | Departments and teams – both at manufacturers and institutes – that are responsible for |

Company information

| Company name | Cevotec GmbH |

| Street | Biberger Str. 93 |

| Zip code | 82008 |

| City | Unterhaching |

| Country | Germany |

| Internet / Website |

Contact person

| Title | Mr |

| Name | Seiji Suzuki |

| Position | Technical Lead, Fuji Industries Co., Ltd., CF Project Team |

| Personal E-Mail | |

| Phone / Mobile | |

| Language | English |

Contact person 2

| Title | Mr |

| Name | Anil Mertol |

| Position | Sales Manager |

| Personal E-Mail | |

| Phone / Mobile | +49 89 2314 165 52 / +49 151 7060 3863 |

| Language | English, Deutsch |

SIGNUP

| Username | cevotec |

PROJECTS

| Project List | GAB Japan 2025 Leichtbau |

| Projects WebSite |

TAGS

| TAGS | #robotics, #lay-up, #automation, #composites, #aerospace, #FiberPatchPlacement |